The field of construction has always been an industry ripe for innovation, and the advent of robotics represents one of the most transformative advancements to date. As we look to the future, the role of robotics in construction is poised to become even more significant, bringing forth the potential to revolutionise processes, enhance safety, and increase efficiency in a myriad of ways.

Robotics and Streamlining Operations

One of the most impactful ways robotics is changing construction is by streamlining operations. With robotics, labour -intensive tasks that once took days can be completed in hours, freeing up human workers to focus on more complex tasks that require specialised skills.

Automation of Repetitive Tasks

Robotic systems excel at performing repetitive tasks with a high degree of precision and consistency. Brick-laying robots, for example, can lay thousands of bricks a day, far outpacing human workers. They can work round-the-clock without fatigue, ensuring that projects stay on schedule and are completed in less time. Other robots are designed to carry out tasks such as tying rebar, drilling, and digging trenches.

3D Printing

In the sphere of 3D printing, robotics is playing a major role in reshaping the construction landscape. Robotic arms equipped with 3D printers can construct everything from building components to entire structures, including homes and bridges. The technology allows for greater design flexibility, less material waste, and faster production times compared to traditional construction methods.

Building Information Modelling (BIM)

Robots can also play a critical role in integrating with Building Information Modelling (BIM) systems. BIM is a digital representation of physical and functional characteristics of a facility. Robots can use this data to accurately execute plans, reducing errors and enhancing the efficiency of construction projects.

Robotics and Enhancing Safety

Beyond streamlining operations, robotics also has the potential to significantly enhance safety on construction sites.

Performing Dangerous Tasks

Robots are being used to perform tasks that are dangerous for humans, reducing the risk of workplace injuries. For example, demolition robots can safely and efficiently take down structures, and drones can inspect high or difficult-to-reach places without risking a worker’s safety.

Heavy Lifting

Robots are also increasingly being utilised for heavy lifting tasks, reducing the physical strain on human workers and decreasing the risk of injuries. Exoskeletons, a type of wearable robot, provide physical strength while reducing fatigue, which can be particularly beneficial for tasks that require heavy lifting or repetitive movements.

Safety Monitoring

Robotics technology, such as drones and autonomous vehicles, can be used to monitor construction sites for safety compliance. They can identify potential hazards, monitor work progress, and ensure that safety protocols are being followed. This proactive approach to safety can help prevent accidents before they occur.

The Future Outlook

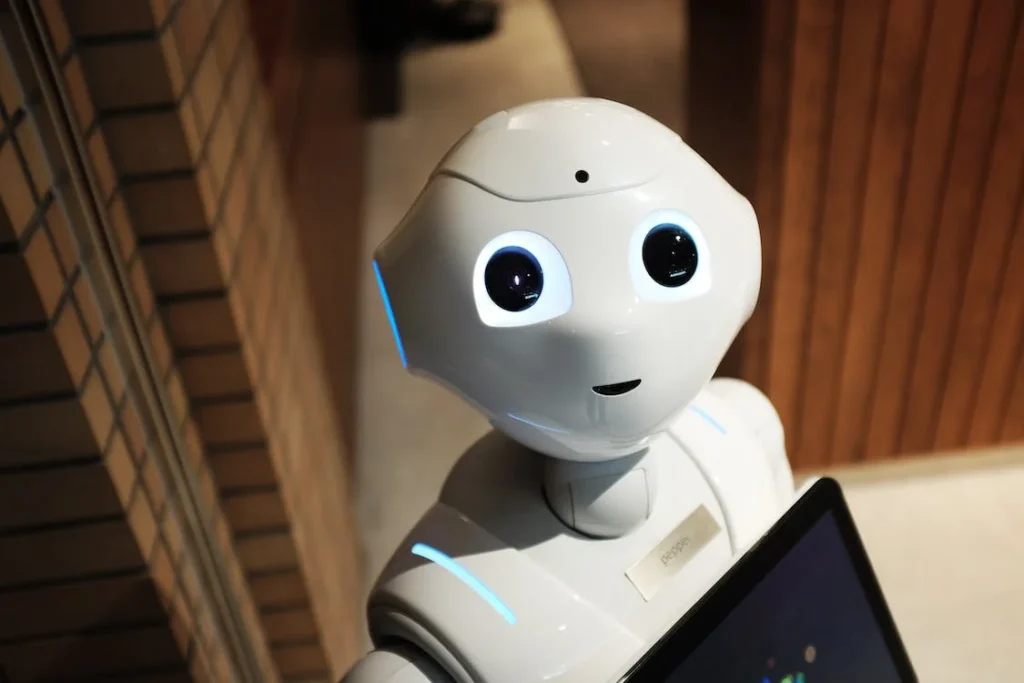

The adoption of robotics in construction represents a shift towards increased automation, efficiency, and safety. However, it’s also important to note that this doesn’t mean human workers will become obsolete. Instead, the future will likely involve a collaborative approach, where human workers and robots work side-by-side, with each doing what they do best.

The future of construction robotics is likely to be shaped by advancements in artificial intelligence (AI), machine learning, and the Internet of Things (IoT). With AI and machine learning, robots will become more intelligent and capable of handling more complex tasks. IoT technology, on the other hand, will enable better communication and coordination among robots, tools, and workers on the construction site.

Innovation and Interdisciplinary Collaboration

As we delve deeper into the future of robotics in construction, the trend is likely to involve more interdisciplinary collaboration. Engineers, roboticists, data scientists, and construction professionals will need to work together to create robotic solutions that fit seamlessly into construction workflows. This trend toward increased collaboration across disciplines promises to foster innovation, delivering solutions that address the specific needs of the construction industry.

Training and Skill Development

With the introduction of robots in construction, there will also be an increased need for skill development and training for the human workforce. Workers will need to be trained to operate, supervise, and maintain robotic systems. This shift in skills does not necessarily mean a loss of jobs, but rather a transformation of roles. The emergence of robots will create new job opportunities related to robotic system operation, maintenance, and programming.

Legal and Regulatory Considerations

As we envision a future where robots become common on construction sites, legal and regulatory considerations will also come to the forefront. Issues like liability in the case of robot malfunction, data security, and privacy are likely to become important considerations. Policymakers, legal experts, and industry leaders will need to work together to develop the regulatory framework for this new era of construction.

Sustainability and Environmental Impact

Finally, it’s worth noting the role robotics could play in making the construction industry more sustainable. Robotic systems, due to their efficiency and precision, can significantly reduce waste in construction processes. Moreover, many robotic systems can be powered by electricity, reducing the industry’s reliance on fossil fuels.

Emergence of New Forms of Robotics

With continued advancements in technology, we can anticipate the emergence of new forms of robotics in the construction industry. In the future, we might see the widespread use of swarm robotics – systems where multiple robots work together collaboratively on a task. Inspired by behaviours found in nature such as ants or bees working collectively, swarm robotics can potentially offer benefits in terms of efficiency and redundancy. If one robot fails or if a particular area requires more intensive work, others can step in or ramp up their efforts.

Integration with Other Technologies

As technology progresses, we’ll likely see increased integration between robotics and other emerging technologies. Augmented Reality (AR) and Virtual Reality (VR), for example, could be used to provide operators with enhanced control and feedback when controlling robotic machinery or to simulate construction scenarios for planning or training purposes.

On the other hand, advancements in AI and machine learning can be leveraged to create robots that are not only capable of executing tasks, but also learning and improving over time. This could lead to robotic systems that adapt to their environments and can solve problems on-the-go, reducing downtime and increasing efficiency.

Economic Impact

The economic impact of implementing robotics in construction cannot be understated. While the initial investment in robotic technology can be high, over time the efficiencies they provide in terms of speed, precision, and the reduction of human error, offer significant cost savings. In addition, the capability to work around the clock gives the potential to greatly reduce project timelines, resulting in further economic benefits.

Global Construction Landscape

The implications of robotic technology also stretch to the global construction landscape. For countries dealing with labour shortages in the construction sector, robotics presents a viable solution. It enables tasks to be completed quickly and efficiently, regardless of the labour market situation. As such, we may see a trend of increasing adoption of construction robotics in countries facing such challenges.

Enhanced Project Planning and Management

The influence of robotics extends to project planning and management as well. Autonomous robots equipped with LIDAR or other imaging technologies can quickly and accurately survey construction sites, collecting data that can feed into digital models or simulations. This real-time data can help in making informed decisions, foreseeing potential issues, and ensuring the project stays on track, reducing delays and cost overruns.

Customization and Precision

Robots, with their high precision and flexibility, can also pave the way for increased customization in construction. Robotic systems can easily adapt to design changes and execute intricate designs that would be challenging for human workers. Whether it’s a uniquely designed element of a building or a requirement to adapt to a challenging construction site, robots can handle these tasks with a high degree of accuracy.

Advancements in Material Handling

Material handling is another area where robotics is making inroads. Robotic equipment can automate the process of moving, sorting, and organising construction materials on a job site, which can lead to significant time savings and a reduction in physical labour.

Ethical Implications

As with all technology, the rise of robotics in construction will come with ethical implications. Decisions will need to be made regarding job displacement, re-skilling workers, and ensuring the technology is used responsibly and fairly. The industry will need to work together with policymakers, educators, and community leaders to ensure these ethical considerations are thoughtfully addressed.

Research and Development

Moving forward, significant research and development efforts are required to overcome challenges related to durability, adaptability, and the integration of robots in existing workflows. In addition, research is needed in the development of robust safety standards and practices for human-robot collaboration in construction environments.

The future of robotics in construction promises a realm of opportunities. It signals a shift from traditional construction methods towards a more digitised and automated future. The synergistic collaboration of human skills and robotic efficiency could create an unprecedented era of productivity, safety, and innovation. With continuous research, ethical practices, and embracing change, the construction industry stands at the precipice of a revolution. As robotics technology continues to evolve, we can anticipate a construction landscape that’s progressively safer, more efficient, and more innovative. The future of robotics in construction is not only an exciting prospect but also an inevitable evolution, poised to redefine the industry in the years to come.

For a comprehensive and streamlined approach to construction management, consider using WunderBuild, our innovative construction software solution. WunderBuild empowers you to efficiently handle estimations, project planning, and cost management, ensuring successful project execution from start to finish. Take control of your construction projects and enhance your efficiency with WunderBuild – find out more here.