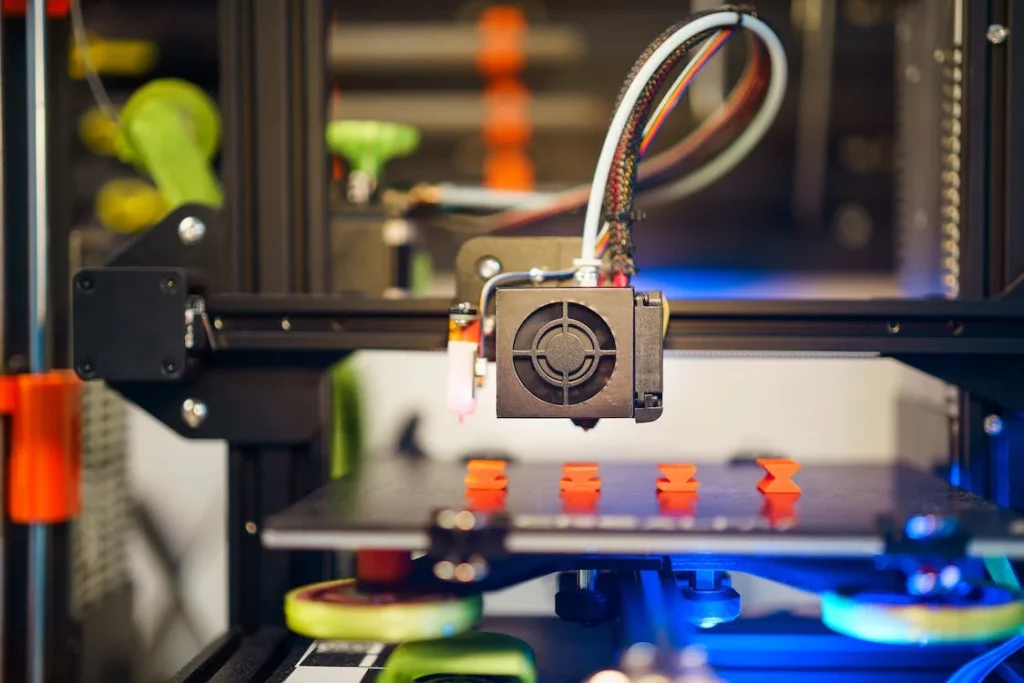

The construction industry, historically known for its traditional building methods, is undergoing a revolutionary transformation with the integration of 3D printing technology. Once confined to the realm of prototypes and small-scale objects, 3D printing has evolved to a point where it can now construct entire buildings. This paradigm shift is not only reshaping the way structures are built but is also unlocking new possibilities for efficiency, sustainability, and architectural design. In this exploration, we delve into the profound impact of 3D printing on construction, from its origins and current applications to the potential it holds for the future of the built environment.

The Genesis of 3D Printing in Construction

1. Origins in Prototyping

3D printing, also known as additive manufacturing, originated in the 1980s primarily for prototyping purposes. It allowed for the creation of three-dimensional objects layer by layer, providing designers with a rapid and cost-effective means of testing and refining their concepts. The technology quickly found applications across various industries, from aerospace to healthcare.

2. Evolution into Construction

The transition of 3D printing from small-scale prototypes to large-scale construction was a natural progression. The construction industry, known for its slow adoption of technological innovations, began exploring the potential of 3D printing to address challenges such as labour shortages, material waste, and project timelines.

Current Applications of 3D Printing in Construction

1. Building Components

One of the primary applications of 3D printing in construction is the creation of building components. Elements such as walls, columns, and panels can be manufactured using 3D printing technology. This approach allows for precision in design and the integration of intricate details that may be challenging to achieve with traditional methods.

2. Whole Structures

Beyond components, 3D printing has progressed to the point where entire structures can be printed layer by layer. This method, also known as contour crafting, holds the potential to revolutionise the construction of residential homes, commercial buildings, and even infrastructure projects.

3. Sustainable Materials

3D printing in construction often involves the use of sustainable materials, such as recycled concrete or bio-based polymers. This aligns with the growing emphasis on environmentally friendly construction practices, reducing the industry’s ecological footprint.

4. Complex Architectural Designs

The precision and flexibility of 3D printing technology enable the realisation of complex architectural designs that may be challenging or impractical with traditional construction methods. This opens up new possibilities for innovative and aesthetically striking structures.

5. Rapid Prototyping

3D printing allows for rapid prototyping in construction, enabling architects and builders to create scaled-down models of structures before committing to full-scale construction. This iterative process facilitates design refinement and reduces the risk of errors during the actual building phase.

The Revolutionary Advantages of 3D Printing in Construction

1. Speed and Efficiency

One of the most significant advantages of 3D printing in construction is its speed and efficiency. The layer-by-layer additive process eliminates the need for time-consuming traditional construction methods, significantly reducing project timelines. This is particularly crucial in addressing urgent housing needs or responding to natural disasters.

2. Cost-Effectiveness

3D printing can potentially lower construction costs by optimising material usage and minimising waste. Additionally, the reduced labour requirements and faster construction timelines contribute to overall cost-effectiveness. As the technology becomes more widespread, economies of scale are expected to further enhance its cost advantages.

3. Customization and Design Flexibility

3D printing offers unparalleled design flexibility and customization. Architects and designers can create intricate and unique structures that cater to specific functional and aesthetic requirements. This flexibility is empowering a new era of architectural creativity.

4. Reduced Material Waste

Traditional construction often generates significant material waste. In contrast, 3D printing is an additive process that uses only the necessary amount of material, minimising waste. This aligns with sustainable construction practices and contributes to a more environmentally conscious industry.

5. Labour Shortage Mitigation

The construction industry has faced persistent challenges related to labour shortages. 3D printing has the potential to mitigate this issue by automating certain construction processes. This shift can redirect human labour towards tasks that require creativity, problem-solving, and oversight.

6. Safety Improvements

3D printing can enhance construction site safety by minimising the need for workers to engage in hazardous tasks. Aspects of construction that are traditionally dangerous, such as working at heights or in confined spaces, can be automated through 3D printing technology.

7. Global Accessibility

3D printing has the potential to address housing shortages on a global scale. In areas with limited access to traditional construction materials and skilled labour, 3D printing can provide a viable solution for rapidly and affordably building homes and infrastructure.

Notable Projects and Innovations

1. ICON and the 3D-Printed Home

ICON, a construction technology company, made headlines with its 3D-printed homes. The company’s Vulcan printer can construct a 350-square-foot home in a matter of hours. These homes are not just prototypes; they have been successfully deployed in various locations, demonstrating the real-world applicability of 3D-printed construction.

2. The BOD Building

Located in Italy, the BOD building is a prime example of the architectural possibilities afforded by 3D printing. Designed by the architecture firm Archea Associati, the BOD building features intricate geometric patterns that showcase the precision and complexity achievable with 3D printing.

3. The 3D-Printed Bridge in the Netherlands

The Netherlands is home to a 3D-printed concrete bridge, a collaboration between the Eindhoven University of Technology and construction company BAM Infra. This project demonstrates the feasibility of 3D printing for creating infrastructure components, offering potential solutions for the maintenance and construction of bridges.

4. Apis Cor’s Construction Innovations

Apis Cor, a construction technology company, has developed a mobile 3D printer that can construct entire buildings on-site. The company’s projects include residential homes and commercial structures, showcasing the versatility and mobility of 3D printing technology in construction.

5. The Dubai 3D-Printed Office

Dubai has been at the forefront of embracing futuristic construction technologies. The city unveiled the first 3D-printed office, constructed using a massive 3D printer. The project not only symbolises Dubai’s commitment to innovation but also demonstrates the practical application of 3D printing in large-scale construction.

Challenges and Considerations

1. Regulatory Approval

The adoption of 3D printing in construction faces regulatory challenges. Building codes and standards may need to be updated to accommodate this innovative technology, ensuring that 3D-printed structures meet safety and durability requirements.

2. Material Standards and Certification

Establishing material standards and certifications for 3D-printed construction materials is crucial for ensuring the longevity and structural integrity of buildings. Consistency in material quality and performance is vital for the widespread acceptance of 3D-printed structures.

3. Scalability and Mass Production

While successful projects have demonstrated the feasibility of 3D printing for individual structures, scalability for mass production remains a challenge. Developing large-scale 3D printers and optimising construction processes for efficiency will be essential for realising the full potential of this technology.

4. Integration with Traditional Construction

Integrating 3D printing with traditional construction methods poses logistical challenges. Construction projects often involve a combination of various techniques, and achieving seamless integration between 3D printing and traditional construction processes is a consideration for widespread adoption.

5. Technological Advancements

Continued technological advancements are essential for pushing the boundaries of what 3D printing can achieve in construction. Innovations in materials, printing speed, and printer size will contribute to overcoming current limitations and expanding the scope of 3D-printed construction.

The Future of 3D Printing in Construction

The trajectory of 3D printing in construction points towards a future where this technology becomes a standard and integral part of the industry. Key trends shaping the future include:

1. On-Site Construction

The development of mobile 3D printers capable of on-site construction is a trend that could redefine how buildings are constructed. On-site printing offers increased flexibility and reduces transportation costs, especially for larger structures.

2. Multi-Material Printing

Advancements in multi-material 3D printing will enable the construction of structures with diverse material properties. This opens up possibilities for creating structures with enhanced strength, insulation, and even integrated smart technologies.

3. Integration with Robotics

The integration of 3D printing with robotics is a promising avenue for further automating construction processes. Robotics can work in tandem with 3D printers to handle tasks such as material delivery, site preparation, and post-printing finishing.

4. Affordable Housing Solutions

3D printing holds the potential to address the global challenge of affordable housing. By streamlining construction processes and reducing costs, 3D-printed homes could provide viable solutions for housing shortages in both developed and developing regions.

5. Advanced Sustainable Materials

The evolution of sustainable materials for 3D printing in construction will contribute to environmentally friendly building practices. Materials derived from recycled sources and bio-based polymers are likely to become more prevalent in the construction of 3D-printed structures.

6. Collaboration and Standardization

Collaboration among industry stakeholders, including architects, engineers, regulatory bodies, and technology developers, will be crucial for the successful integration of 3D printing into mainstream construction. Standardisation of processes and materials will streamline regulatory approval and facilitate widespread adoption.

The impact of 3D printing on construction is nothing short of revolutionary, ushering in a new era of efficiency, sustainability, and design possibilities. From building components to entire structures, 3D printing is challenging the conventions of the construction industry and unlocking unprecedented potential. As technology continues to advance and stakeholders collaborate to address challenges, the future holds exciting possibilities for the widespread adoption of 3D printing in construction. The buildings of tomorrow may very well be shaped layer by layer, marking a transformative chapter in the evolution of the built environment.

Amidst the groundbreaking shift towards 3D printing in construction, WunderBuild emerges as the quintessential partner for navigating this innovative landscape. With its sophisticated project management and scheduling tools, WunderBuild is uniquely equipped to complement the precision, efficiency, and sustainability that 3D printing brings to the industry. As you explore the vast possibilities of constructing buildings layer by layer, discover how WunderBuild can streamline your projects, ensuring they meet the futuristic standards of efficiency and design innovation. Embrace the future of construction with WunderBuild here.